frequently asked questions

Building sand is made up of fine to medium grained particles, between 0.2 mm and 0.7 mm in size, which are rounded and uniform in size. When building sand is mixed with cement and water, it makes a workable mortar mix which is sticky, capable of being squeezed into gaps and supporting the weight of several bricks or blocks but does not flow. A fairly uniform colour is also important for visual appearances.

Sand worked at sand and gravel quarries is a mix of coarse sized sand up to 3 mm in size and is usually angular in shape which means it is unsuitable for mortar mixes.

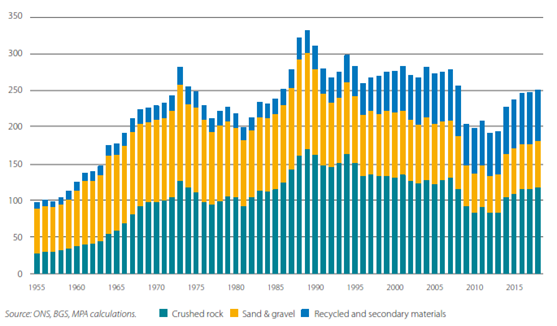

Aggregates are crushed rock, sands, gravel, and recycled and secondary aggregates; used by the construction industry, with an estimated 251 million tonnes used in 2018. Recycled and secondary aggregates contributed 71 million tonnes of that total and make up around 28% of the amount used. This is split down to 64 million tonnes of recycled aggregates and 7 million tonnes of secondary aggregates.

GB aggregates supply (in millions of tonnes)

In terms of aggregates use the UK is below the EU average. In 2016 the EU average use per person was 5 tonnes compared to the UK figure of 4 tonnes.

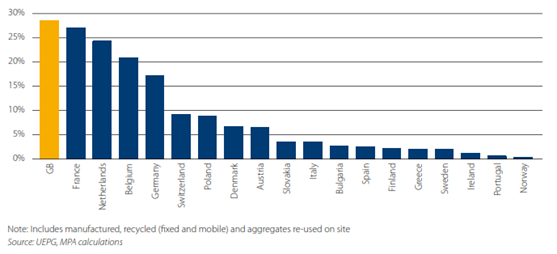

The UK has the highest percentage of recycled and secondary aggregate use in Europe. The main drivers for this in the UK have been environmental concerns and a tax on rock, sand and gravel extraction, with nearly £400 million paid in 2016. This leads to economic benefits in using recycled and secondary aggregates.

Share of recycled and secondary supply 2018

Recycled aggregates are primarily generated from construction work when buildings are demolished and to a lesser extent road resurfacing. Demolition waste comprises concrete and brick which when crushed down produces a mix of angular coarse particles and dust and are suitable for bulk fill uses and some concrete mixes. The road resurfacing waste comprises a mix of rock and oil based bitumen and this is primarily reused to resurface existing or new roads.

Secondary aggregate sources are varied and comprise wastes from industrial processes such as steel making, china clay production and energy from waste plants. The majority of these materials are of a coarse angular nature. A small proportion of china clay waste when processed is capable of meeting the mortar sand requirements. As this material is located in Cornwall and given a lack of local sand in Cornwall and Devon it is used to help meet their own local requirements.

The supply of recycled aggregate is limited by the amount of demolition activity and that of secondary aggregates is limited by the amount of industrial activity in those sectors.

Given limited supplies of recycled and secondary materials and their physical characteristics, they do not meet the requirements of a building sand, consequently there is no substitute available.

The Mineral Products Association (MPA) is a trade body that represents companies that supply aggregates, concrete products including mortar sands and asphalt for road surfacing materials to the construction industry. The MPA monitors activity in the construction sector along with material used. The above information is sourced from them materials.

The MPA has calculated that it takes 200 tonnes of aggregate to build a typical home with 12 tonnes of mortar.

Building sand is a naturally occurring material that was deposited in limited areas over several geological periods under shallow sea conditions. It is therefore naturally limited in where it is available.

Much of the UK is covered by urban areas, National Parks, Area of Outstanding Natural Beauty (AONB) and other designations. The area of the sand resource is therefore further geographically limited and often constrained by physical and national environmental designations.

Hampshire County Council in developing their Minerals & Waste Plan considered all potential areas and concluded that the mineral sites put forward for inclusion were “the most sustainable, deliverable and acceptable options in terms of the environment and local amenity and best meeting the objectives of the Plan.” The Purple Haze site was included to provide a long term supply of building sand to help meet the needs of the construction industry.

The land is currently managed by Forestry England who lease it from the landowners, the Somerley Estate. They will continue to manage the land until such time as it is needed for extraction. As the site is divided into phases Grundon would only take control of each phase as it is required for extraction. Upon the completion of the restoration of each phase it will be handed back to Forestry England.

The site is managed as a commercial operation by Forestry England who fell and replant trees on a regular basis. This produces a variety of landscape features from mature woodland to areas of tree saplings and open areas depending on the maturity of the trees.

The phased working of the site over a period of time would leave much of these features intact. It is only when a phase is taken for extraction that any trees would be removed. The phase is restored the following year as an open area or replanted with trees.

The main difference will be the change to land levels with the lowering of the land by an average of 8 metres, the equivalent of a two storey house.

These changes would initially create a more open landscape that develops as the planted trees mature in the restored phases.

The site has been subject to various ecological surveys and these have informed the baseline against which a biodiversity gain will be measured. A management plan will be drawn up for the life of the site that will guide the long-term management and ensure a 10 percent biodiversity gain is achieved, as sought by emerging Government policy for new development.

The tumuli is a non-designated heritage asset. It has been examined by Historic England, the Government’s body for the historic environment, and found to be severely damaged and of a low quality. It will be investigated and recorded by qualified archaeologists under the supervision of Hampshire County Council during the working of that area. The investigation will provide an opportunity to understand more about tumuli in the area.

Yes – we do not intend to change access arrangements. If a temporary track closure is required another route would be provided.

Aggregates are a low value bulky material and their transport cost adds a significant cost to the delivered price, therefore suppliers nearest to the point of use have a competitive advantage.

The area to the north of Verwood is predominantly rural with no large towns to supply. If vehicles were delivering to Salisbury, for example, it would be a shorter and quicker journey to travel south to the A31 and then travel via the A338. Other sand suppliers would be nearer to Blandford Forum and Shaftsbury, therefore likely to service those areas. We therefore consider that nearly all traffic will head south, traffic northbound from the site would be limited to demand in Verwood and its immediate area.

The numbers of vehicles are expected to be 5 per hour. This level of use would not be sufficient to impact on traffic flow.

The geology of the area comprises a thick clay band over the sand. The ground water is 2 metres below the surface and feeds directly down to Ebblake Bog SSSI. The area is not commercially viable to work due to the thickness of clay and remain above the ground water. To be viable, sand would need to be worked in the ground water zone and this could have potential impacts on Ebblake Bog SSSI.

A small quantity of sand and gravel was found during the site investigations. This was a thin layer over a small part of the site. The material would be worked at the same time as the sand and separated by the processing plant.

We would use a series of well established, industry best practice techniques, which are used extensively across the country to reduce potential impacts during all stages of quarry development and subsequent restoration.

Potential sources of noise and dust could include:

• sand processing

• site vehicles handling sand

• reversing bleepers

• central sand transport conveyor

• customer HGVs

These potential issues can all be addressed by effective site design and management, as potential impacts are well understood. At Purple Haze, best practice management would include:

• use of electric sand processing plant and conveyors

• operating below ground level within the excavation

• designing one way vehicle systems to eliminate the need for reversing bleepers and warning alarms

• monitoring all moving equipment like the conveyor belt, processing plant and site vehicles

• use speed limits on internal roads

• use an onsite mobile water tank to spray internal roads and sand storage area

• using an on-site road sweeper

• the sand is naturally damp when it is extracted and after screening and washing it remains damp when stored prior to sale

• locating operations such as the processing plant away from access tracks

The operation would be subject to regular monitoring by Grundon – Hampshire County Council will independently inspect the site usually every three months.

The Blue Haze site is a landfill accepting household and similar commercial waste. The site operates under a containment cellular system to enclose the waste using clay extracted from the site. The clay needs to be worked and stored which takes up space. The landfill containment cells are designed to be of a certain size that looks to maximise the amount of waste in each. Each cell will last for several years and several cells are open being prepared, in operation or being restored.

The Purple Haze site design relates to a phased sand extraction operation where each phase lasts for a year. This is how Grundon prefers to operate as soils and clays do not need moving into and out of storage.

There is no importation of waste with the Purple Haze development.

We have used independent, specialist consultants to prepare detailed professional reports on all aspects of the proposed development. The outcomes of their research will be published and submitted as part of the planning application and accompanying Environmental Statement that incorporates the results of the Environmental Impact Assessment (EIA). Hampshire County Council will employ its own specialists to assess our technical reports.

This section will be updated as required to respond to new Frequently Asked Questions.